Types of Thermal Sprays

- Electric Arc Wire (EAW) Spraying

- Flame Spray Powder or Wire

- HVOF & HVAF

- Plasma Spraying

- Cold Spray

Because of the various types of thermal spray applications and their effects on the operation of dust collectors, it is important to identify your specific thermal spray operation. Each process involves different shaped and sized particulate along with varying loads. Additionally, strict safety procedures need to be addressed as certain thermal spray operations can be explosive and/or flammable. Let Camfil APC’s expertise in this application help you to put in a safe dust removal system.

Safety Considerations

The potential for fire and explosion is very real when dealing with Thermal Spray and dust collectors. It is imperative that Camfil APC be contacted for proper explosion venting and other safety concerns. Explosion vents, sprinkler kits, flame retardant cartridges and possibly spark traps all need to be addressed during the proposal phase of the sale.

Thermal/Flame Spray before Farr Gold Series turned on

Thermal/Flame Spray after Farr Gold Series turned on

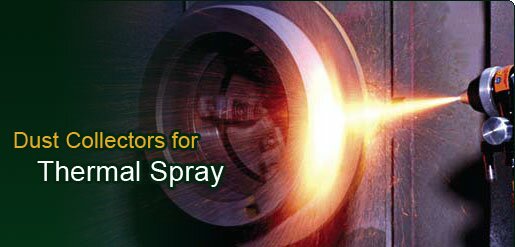

Dust Collectors for Thermal Spray / Flame Spray

-Benefits of the Farr Gold Series:

- High entry cross flow, inlet eliminates upward can velocities that can hold fine powder up in the filters reducing re-entrainment of the fine particles.

- Vertically arranged filters shed all the metal particulate - vs. horizontal filters which allow the metal to build on top of the filter.

- High efficiency filters stop 99.99% at 0.5µ of the dust! Special treated filter media repels the fine particle for lower pressure drop and long filter life.

- Gold Cone® provides 25% more media for long service life.

Next: Sizing Recommendations for Thermal Spray Applications

Follow. Connect. Watch. Learn.