Blasting

GS20 on Aluminum Shot Blasting |

GS96 on Wheel Blasting Application |

GS20 on Sand Blast Room Ventilation |

GS4 on Shot Peening at Progressive Surface |

Model GS12 on Metal Shot Blasting |

GS96 successfully handling foundry sand containing lead and other metals. |

Farr GS6 on shot blasting application at Brewton Iron Works. |

Four Farr Gold Series dust collectors on a blasting application at ASC. |

Farr Gold Series GS8 on a shot blasting application at Crown Equipment. |

Farr Gold Series GS10 and GS6 on abrasive blasting and recovery at Hardi Australia. |

GS32 on a blasting application at Bisalloy Steel. |

Top of page

Chemical Processing

Stainless Steel GS6 collecting extremely fine pigment powder |

GS16 on Fumed Zinc Oxide at United Precious Metals |

GS32 on Plastic Dust |

GS24 on Regenerative Thermal Oxidizers at Crown, Cork and Seal |

GS16 on Plastic Powder Mixing at General Cable |

Stainless steel GS6 units Extremely Fine Pigment Powder |

GS32 on Silica Fines and Flakes at Munters, Inc. |

GS6 on Powder Mixing at Technic, Inc. |

GS on Magnesium Oxide, a fire retardant agent |

GS10 at Amway Global |

Gold Series at Entek International |

Gold Series GS16 on Potassium Sulfate |

Top of page

Fiberglass/FRP

GS48 on Chopped Fiberglass at Johns Manville International |

Another GS48 on Chopped Fiberglass |

Gold Series GS6 on a fiberglass application at Premix |

Top of page

Fibrous/Fluffy Dust

GS4 on Hay Compacting at Ward Rugh, Inc. |

Twin GS96 Units on UHMV Board Manufacturing |

GS32 on PVC Dust at Advanced Trim Works |

GS12 unit on Foam Mold Process at Bridgestone APM |

GS16 unit on Foam Mold Process at Bridgestone APM |

Model GS32 on Hay Press Processing at Ward Rugh, Inc. |

Top of page

Fine Powder

GS36 on Masonry Dust |

GS16 with Safety Monitoring Filter on Powdered Cosmetics |

GS12 and High Vacuum 4HV on Toner Cartridge Dust |

Farr Gold Series GS40 installed at Tri-Gemini on a fine powder application. |

Top of page

Food Processing

Stainless Steel GS4 on Powdered Food Ingredients at Maruchan, Inc. |

GS24 on Dried Food Ingredients at Nestle Corporation |

GS10 being installed at Cereal Ingredients, Inc. |

GS16 on a Pastry Food application |

Farr Gold Series GS12SQ on a food processing application at Midwest PMS. |

Top of page

Laser and Plasma

GS24 on Plasma Cutting |

GS10 on Plasma Cutting at Fisher Snow Plow |

GS8 on Laser Cutting |

GS16 on Plasma Cutting |

GS16 on Laser Cutting Application |

GS4 on Laser Cutting Fumes, connected to a zipper duct |

GS8 on Plasma Cutting |

GS16SQ on a Plasma Table Cutting Aluminum |

GS8 on a Plasma Table application |

GS32 on Plasma Cutting at Trail King Industries |

Gold Series GS20 industrial dust collector on a plasma cutter |

GS48L on Plasma cutting at Jeffboat |

GS4 on a plasma cutting operation at Kawasaki |

Farr Gold Series GS24 installed at Chatham Steel on a plasma cutting table application. |

Top of page

Metalworking

Gold Series Booths on sanding and grinding application at Ogihara American Corp |

GS32 on Fumes from Metal Scrap Processing at Enviro-Chem |

GS36 on Grinding, Buffing, Polishing Carbon Steel at Western Forge |

GS108 on Heavy Torch Cutting of Sheet Metal at Brandenburg Industrial |

GS4 on a Metal Cut off Saw |

GS12 collecting Platinum Dust in a recycling process |

GS24 on Steel Shot and Grit Abrasive manufacturing |

GS20 dust collector installed at Masterloy Products Company |

Model GS16 on an aluminum linishing process. |

Model GS12SQ on Steel Grinding at Héroux-Devtek. |

Farr Gold Series GS108 collecting sand on a metal working application. |

Top of page

Mining

Gold Series dust collector operating at a conveyor to conveyor transfer station. |

Two GS96 Units at a Nickel Mine |

Gold Series capturing fugitive dust over a conveyor |

Gold Series units on crushing copper ore |

Gold Series on a mining mill conveyor transfer point |

Coarse Ore Storage Bin Vents |

Gold Series bin vents on coarse ore storage building near mining conveyor |

GS on a Copper Mine Crushing Line |

Top of page

Paper Scrap

GS108 on Corrugated Box Dust at Packaging Corp of America |

GS84 on Paper Trim Scrap |

GS2 used as a bin vent |

GS108 on Paper Scrap |

GS48 on paper trim and dust from a shredder |

Customer uses view port to inspect hopper on GS16 on Paper Dust at Trader Publishing |

GS144 on Printer Paper Trim and Dust |

Top of page

Pharmaceutical

Two GS60 Units on Powdered Dust at a Vitamin Manufacturer |

GS8 Camatin bag in bag out unit on a pharmaceutical application |

Multiple GS Camtain units on a pharmaceutical application |

Gold Series Camtain dust collector with bag in bag out safe change filter system |

Gold Series Camtain model GS16 central dust collector installation |

Gold Series Camtain with continuous liner containment system for dust discharge |

Another proper application and installation of the Gold Series Camtain |

Two Gold Series Camtain CGS6 models on a pharmaceutical application in Guayama, P.R. |

Two GS8 collectors at BOSCH Manesty |

CGS2 on pharmaceutical dust and general suction from several hoods. |

Top of page

Recycling

Model GS32 on Paper and Glass Recycling |

Top of page

Rubber Grinding

Gold Series Units and Cyclones on Rubber Automotive Belt and Tire Grinding at Dayco Automotive. |

Three GS12 Units on Rubber Grinding |

Top of page

Sanding

Top of page

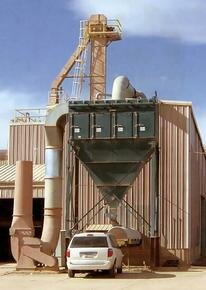

Seed Processing

GS12 and Two GS20 Units on Fugitive Dust from Corn Seed Processing at Pioneer Hi-Bred |

GS16 on seed processing at Mycogen |

GS32 on Corn Shelling |

Gold Series Dust Collectors at Pioneer Hi-Bred |

GS24 on dust from a corn sheller and cleaner |

Top of page

Solar Panel Fabrication

GS24 units on a solar panel manufacturer in Massachusetts, USA |

GS56 on air extraction from furnaces for a solar panel manufacturer in Norway, U.K. |

Top of page

Thermal Flame Spray

Farr Gold Series GS48 and GS12S on a thermal spray application at Impreglon UK. |

GS32 on a thermal spray application |

GS24 on a HVOF Thermal Spray application |

Two GS40 models on a thermal spray application |

Two GS32 models on Thermal Spray at Vishay Components |

A GS36, GS48, and GS60 on a thermal spray application. |

Top of page

Welding

GS48 on Welding Fume at Farr APC High Bay Plant |

GS48 on Auto Welding Smoke at Nissan North America, Inc. |

GS32 on Plasma Welding |

GS24 on Welding Fume at Bobcat Company |

GS on Welding Smoke at Nissan North America, Inc. |

GS on Welding Smoke at Nissan North America, Inc. |

Two GS12 dust collectors on a welding application at Toyo Seat, USA. |

GS20L Special on Combined Ambient and Source Welding Fume |

GS12SQ on Weld Smoke |

GS20L Special on Combined Ambient and Source Welding Fume |

Farr GS6 at General Sheet Metal Works on welding fumes. |

Farr Gold Series GS6 on a welding application. |

Farr Gold Series on a welding fume application at General Sheet Metal Works. |

GS40 on a welding application at Waconia Manufacturing |

Top of page

Woodworking

GS12 on Woodworking |

GS8 on Woodworking at Wood Technology |

GS16 on Woodworking at Vigilant Inc |

GS16 on Woodworking at Weitco Stair Products |

GS48 on Wood Finish Sanding at New England Wood Craft |

GS16 collecting MDF, plywood and Particle Board dust on a Woodworking application |

Twin GS16 units on a Woodworking application |

GS16 on Woodworking Dust at Reinke Manufacturing |

Model GS48L on a woodworking application at Colony Display Systems. |

Follow. Connect. Watch. Learn.