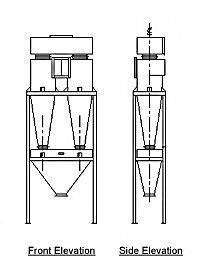

FD Cyclones

High Efficiency Centrifugal Particulate Separators

These high efficiency cyclones are frequently used as product receivers, as precleaners to high efficiency fabric-type dust collectors, or as independent collectors for coarse dusts.

Advantages

- Stable pressure drop for a given gas flow

- Constant efficiency for a given particulate condition

- No moving parts; no replaceable filters

- Ability to handle extremely high dust concentration

- High temperature capability

Efficiency

On industrial coarse particulate, FD Cyclones are 95% to 98% efficient. Efficiency is a function of the physical parameters of the application and the design parameters of the cyclone. Cyclone efficiency increases with:

- Coarse particle size distribution

- Higher product specific gravity

- Lower gas density

- A decrease in cyclone diameter (two smaller cyclones in parallel will have a higher efficiency than one larger cyclone with an equal pressure drop)

- Smaller outlet diameter. An increase in pressure drop also results.

Efficiency and pressure drop are also affected by barrel length, outlet length, inlet configuration, and design of the internal cone. These factors are optimized to result in the maximum possible efficiency at a practical overall size and pressure drop.

Options

The FD cyclone optional components include discharge hopper, scroll outlet and steel support legs. Common hoppers and scroll outlets are available for multiple cyclone configurations.

Next: How a Cyclone Dust Collector Works

Follow. Connect. Watch. Learn.